Understanding the cost factor of crusher wear parts

Filip Naessens

In today's economic climate, the cost base is an important factor in running a successful crushing business. The wear costs associated with wear parts of a crusher can be a significant cost. How important are crusher wear parts in the overall cost equation of operating a crusher and how can operations be reduced costs related to this component?

"Crusher liners" serve several very important purposes in a crusher. The first and most important task is to protect the crusher from expensive or irreparable damage.

The wear material is hard, tough and can withstand plastic deformation without breaking. By having the right chemical composition, with a special manufacturing process, the liners protect the frame of the machine. As a result, they guarantee that the crusher will have many years of service.

"Crusher liners" are wear parts that are processed. It is exposed to the material entering structural components and is designed for the crushing chamber during strength and durability while the liners are crushing. As such, there are different grades designed according to wear resistance, toughness and impact

Should they be replaced when they are completely worn out? If they are not replaced, major damage can be transferred to the crusher itself.

Such damage can take the form of premature bearing failure, cracking of the crusher chamber castings and signs of wear on the crusher chamber castings themselves.

Abrasive process

Since crushing is an abrasive process, the crusher liners protect the structures and components of the crusher by being the main contact surface. The shape of crusher liners, can also have a great effect on the crushing result in terms of particle shape and gradation.

sacrificial parts

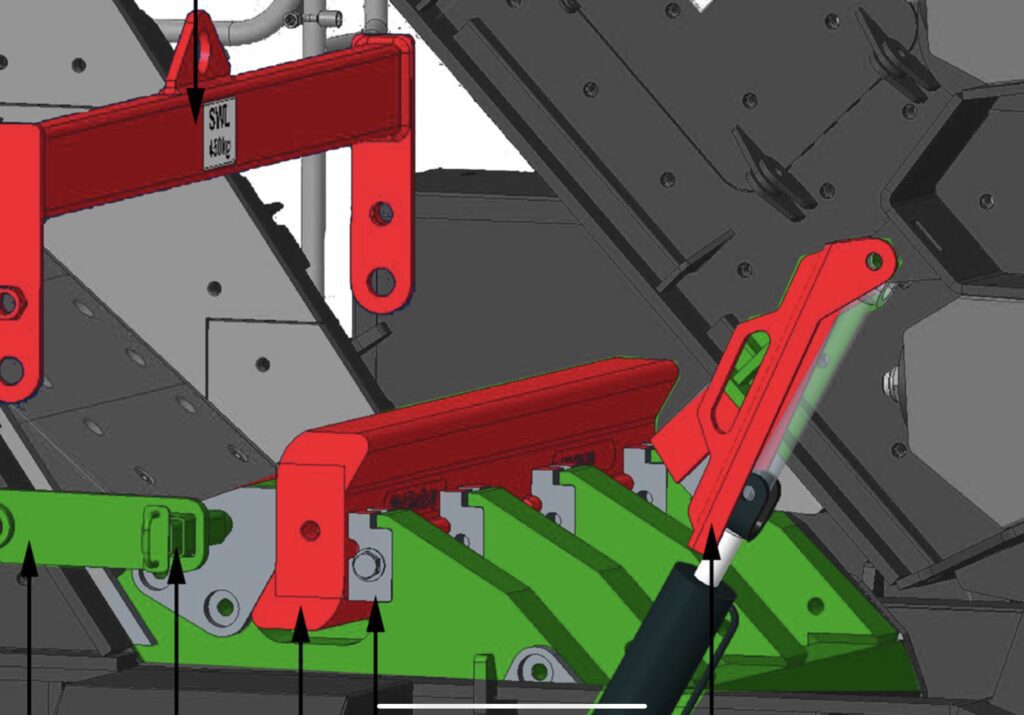

The wear parts of a crusher are the sacrificial parts designed to protect the very expensive machine and extend its life by isolating the structural components of the machine from the materials being processed.

crusherliners

The industrial term,' crusher liners ', refers to a specialized set of sacrificial liners in a jaw or cone crusher. These special liners are subjected to the full compressive forces in a crushing chamber and absorb large amounts of energy.

Profiles

The second essential aspect of crusher wear parts is that they can have complex and intricate profiles.

Lining profiles may look simple, but they create specific and complex force vectors in the crushing chamber.

The liner profiles also determine the material flow paths between them firstly crushing efficiency, secondly crusher throughput, and also influencing wear patterns and physical product characteristics such as size and shape.

The different types of wear parts are designed to maintain the ideal crushing chamber profile while withstanding high crushing forces and wear of the processed material.

The feed profile is a feature that is common and does not receive enough attention from the machine operator. Changing the lining profile can yield significant improvements in throughput and product quality. A benefit that has a greater impact on the bottom line than the wear properties that operators usually focus on.

Another essential function of wear parts of a crusher and probably the most discussed feature, is resisting wear through the breaking process. This feature is probably the one on which customers focus most, sometimes at the expense of the other essential lining qualities.

Contact Naessens Hydraulics for all your required wear parts for crushers Contact Us