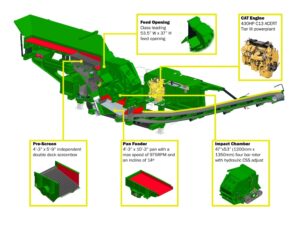

The McCloskey I54 is designed to be the most productive horizontal impact crusher in the sub 50-ton class. This machine is built around an impressive 1200 mm x 1350 mm impact chamber with a 939 mm x 1358 mm feed opening.

With a feed hopper capacity of about 7 m³ and a 1354 mm wide vibrating feeder pan, the crusher is fed through a separate double-deck vibrating pre-screen deck. This ensures that most of the crushing sand is removed before it reaches the crushing chamber, increasing capacity. The pre-screened crushing sand can be discharged to the main conveyor or a side conveyor.

Crushed materials are discharged from the crushing chamber into a large 1354 mm x 4615 mm feed pan. This feeder pan is larger and has a steeper slope than comparable systems, allowing material to be processed quickly in high tonnage applications. This prevents damage to the conveyor belt.

The I54 is powered by a powerful 430-hp C13 ACERT CAT engine, which ensures adequate power, parts availability and Tier III emissions compliance.