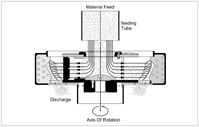

The material to be crushed is placed in the upper hopper and flows through a material tube to the center of the closed rotor. The rotor rotates at a high number of revolutions per minute, throwing the material away from the rotor with a powerful centrifugal force. When the material hits the inside of the crushing chamber, impact occurs and the material is broken. The degree of inertia of the material determines how the cubic end result forms. Finally, the broken material falls through the bottom hopper as a result of gravity.

The natural process of impact and grinding, where the material collides, results in the formation of particles similar to natural sand. This gives the end result the characteristic shape of natural sand.

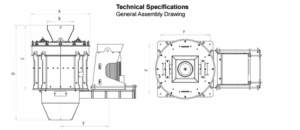

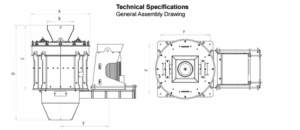

This Rematech RVSI100 makes it easy to change the operation from stone-on-stone to stone-on-metal. By adding anvil rings and stone combinations to the crushing chamber, the machine can be modified for even higher production profitability. Best of all, this modification can be quickly and easily installed on the existing stone-on-stone model, without having to replace the entire machine.