Quality is standard and built for the toughest conditions

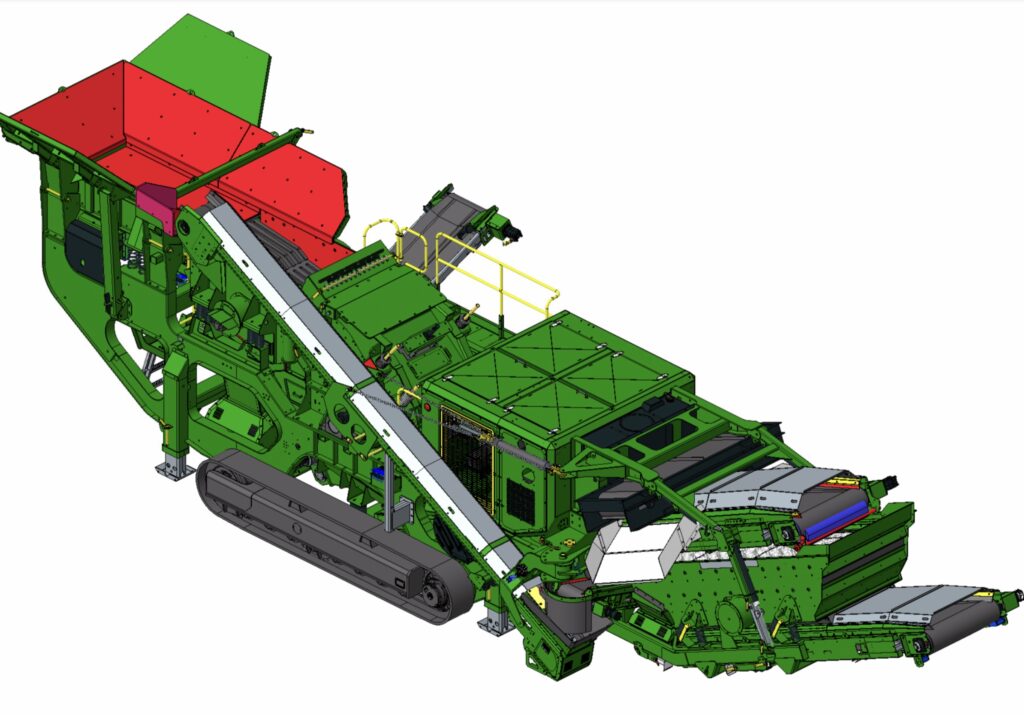

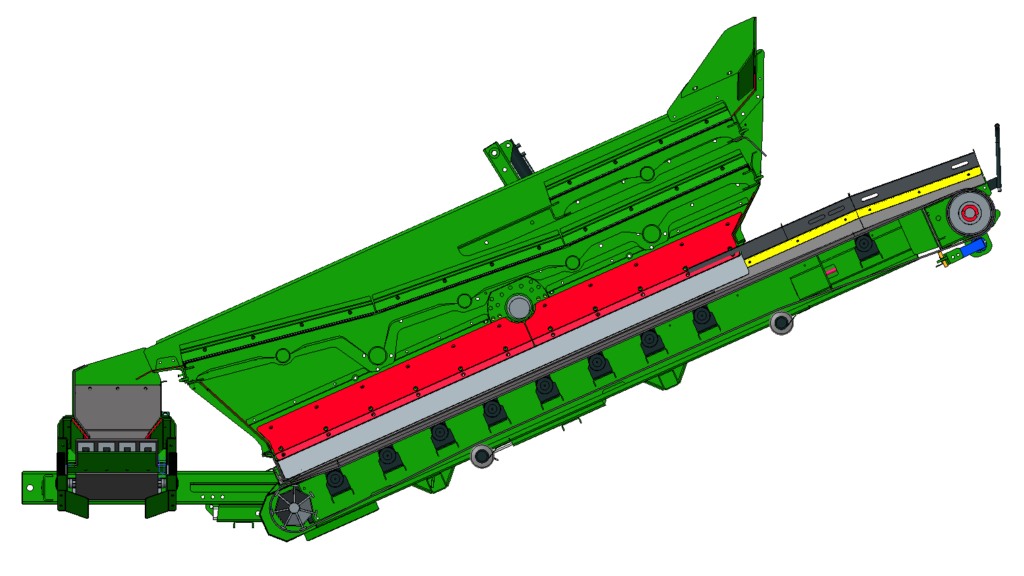

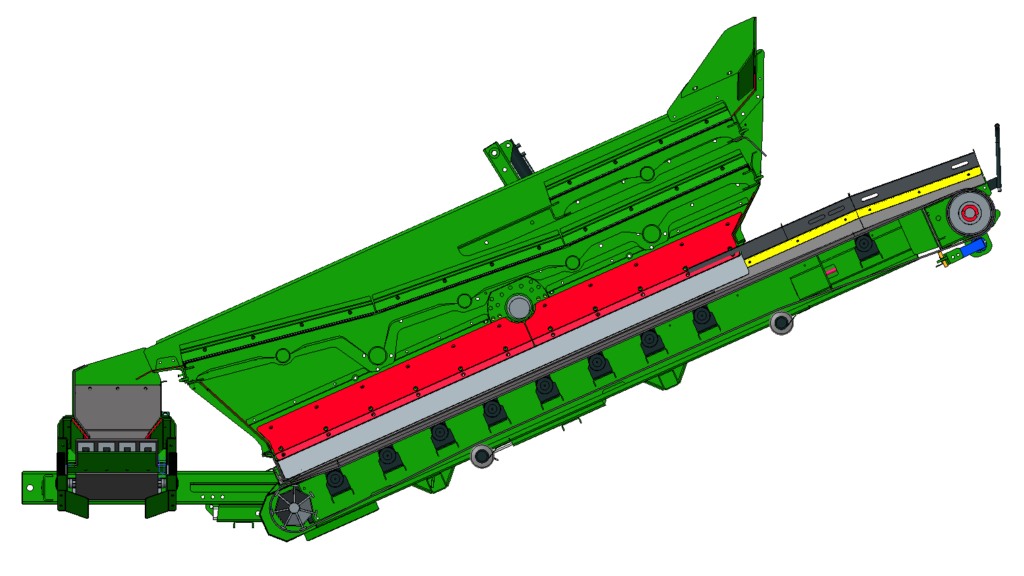

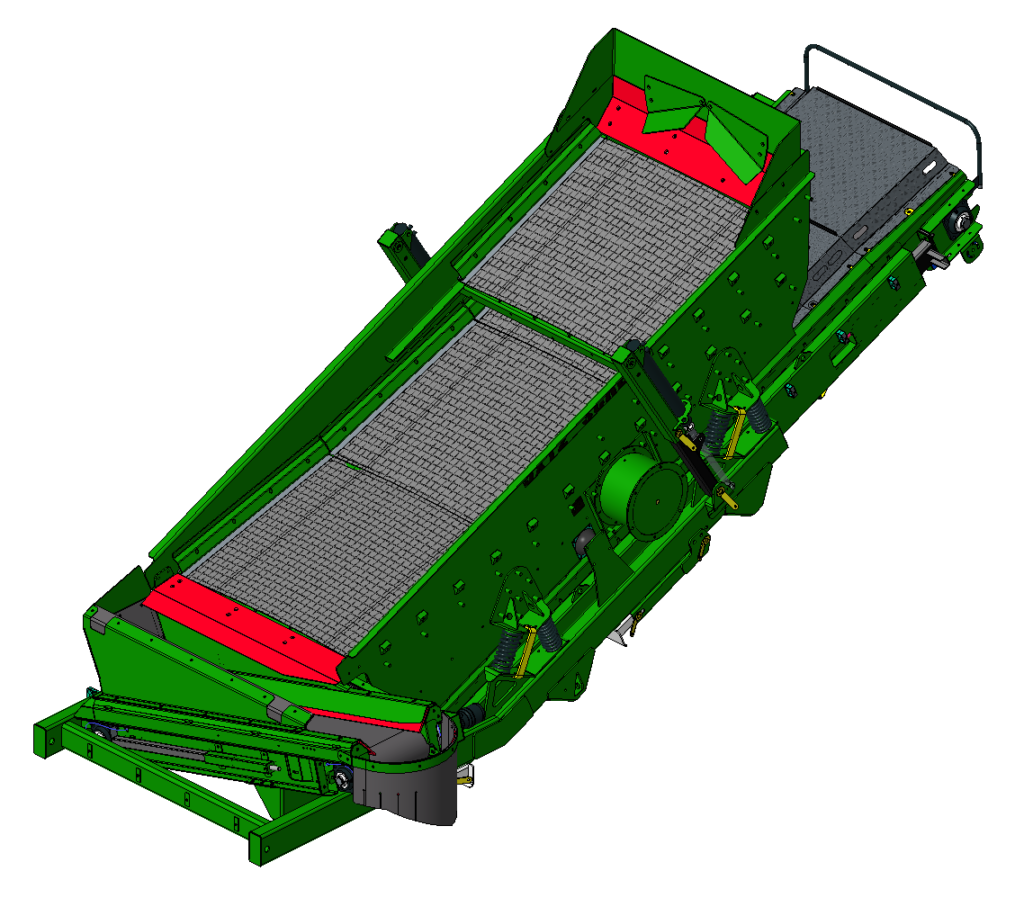

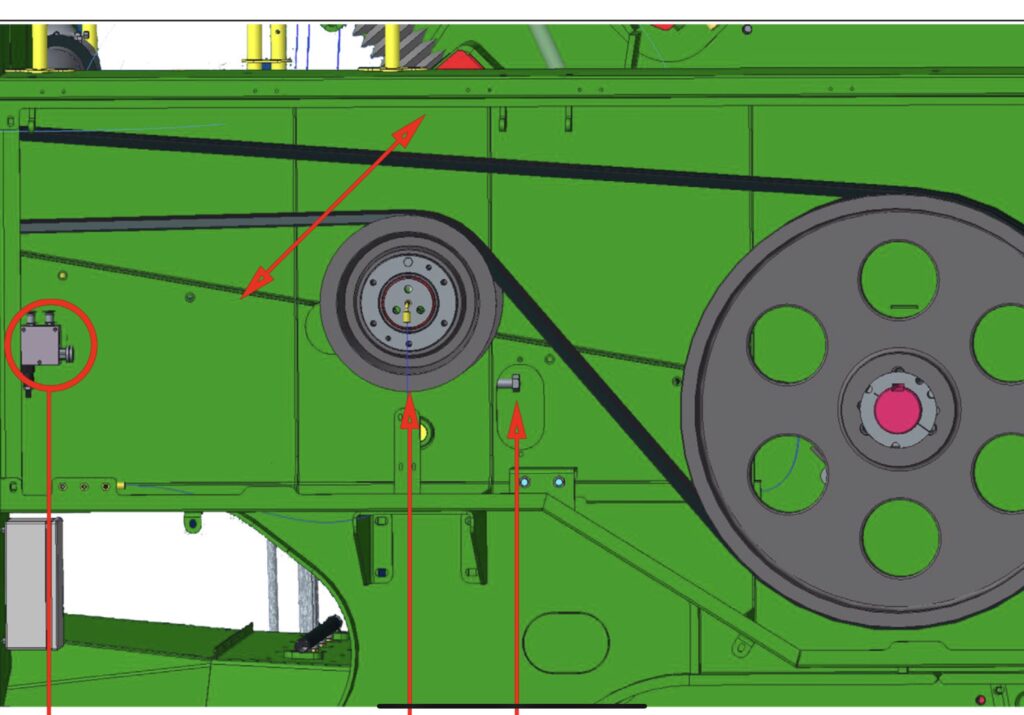

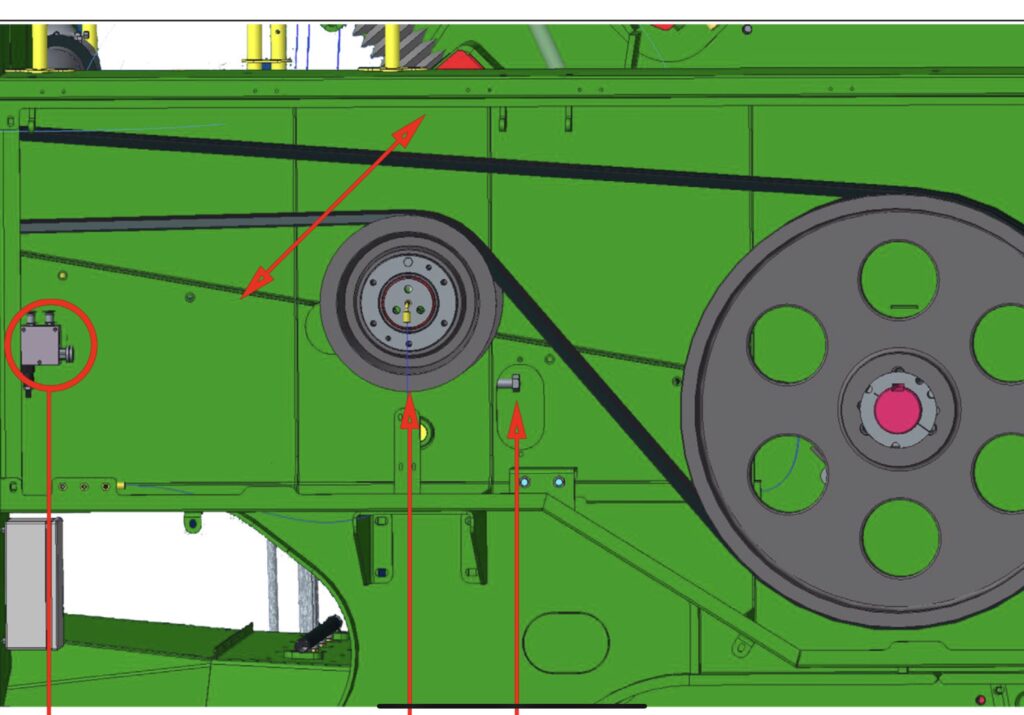

Heavy mobile debris crusher McCloskeyI54RV3

Percussion crusher for heavy recycling applications with or without possible options and with open or closed circuit traps in the weight range up to 70 tons

- 1200 mm x 1350 mm wide impactor

- 510HP Volvo Penta D13 engine

- hydraulic folding feed bunker

- hydraulic folding conveyors

- quick startup time

- open chassis design for easy maintenance

- heavy-duty execution vibrating chute under crusher outfall

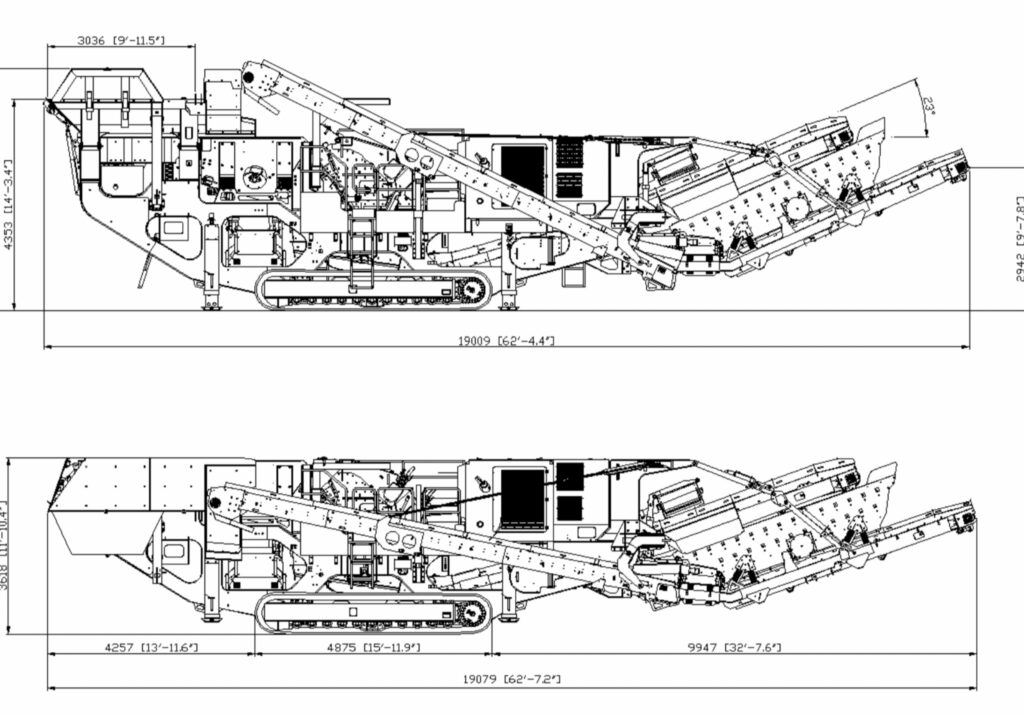

No need to disassemble or assemble parts to transport the machine from one job site to another.

Quick loading and unloading on a flatbed trailer and startup within 15 minutes of arrival at the yard.

There is a progressive flow area for processing materials through the machine. Each component is wider than its predecessor, which minimizes the chance of obstructions and blockages in the flow.

All steel surfaces in the feed bunker that come into contact with the materials to be processed are covered with interchangeable panels made of Hardox.

The chassis is designed in a wide and robust design to accommodate the wide discharge tires and provide easy access for maintenance and cleaning.

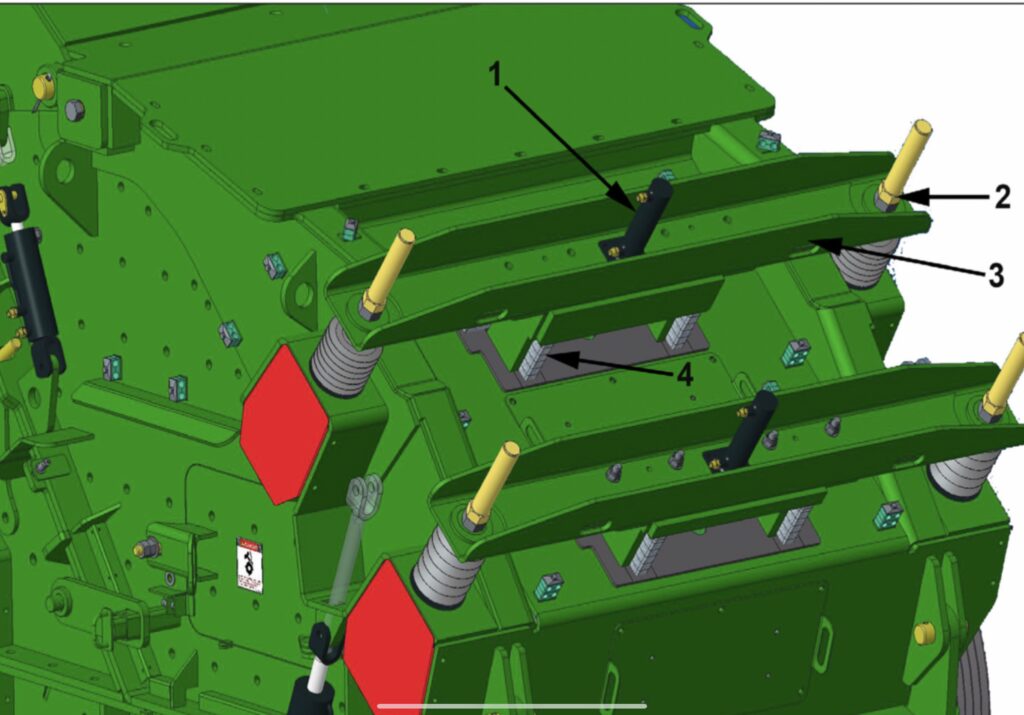

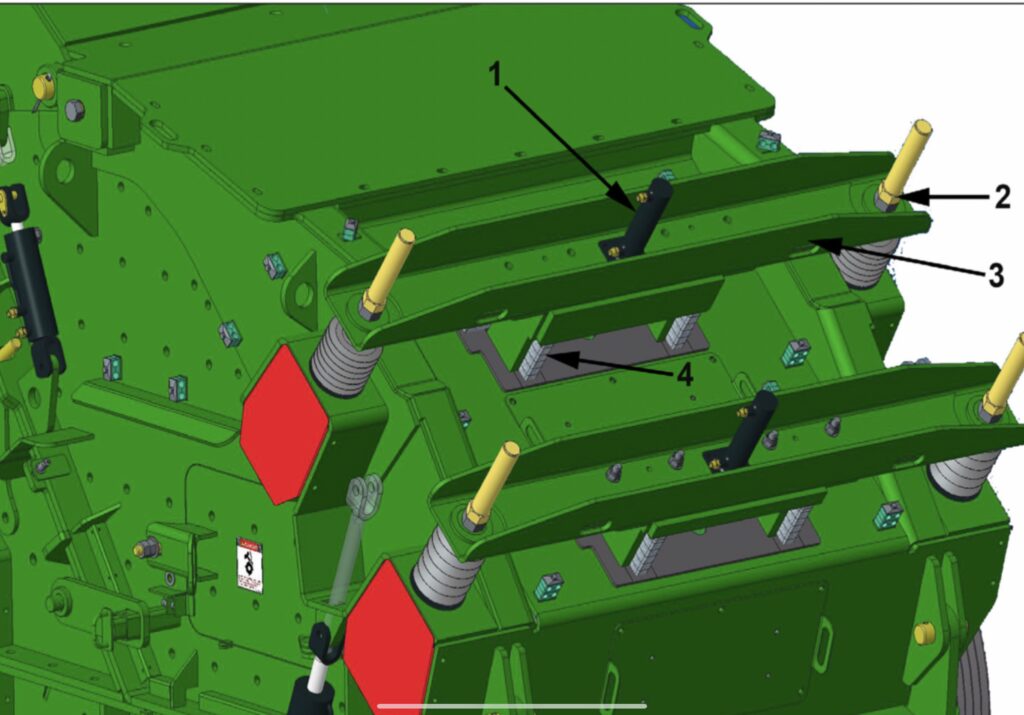

The machine is equipped with four hydraulically adjustable support feet, each independent, which provide stability during operation, reduce vibration and accurately adjust the machine. This contributes to optimal use of the impact strips.

A double-pole permanent magnet adjustable in height is supported by a support frame that is hydraulically adjustable.

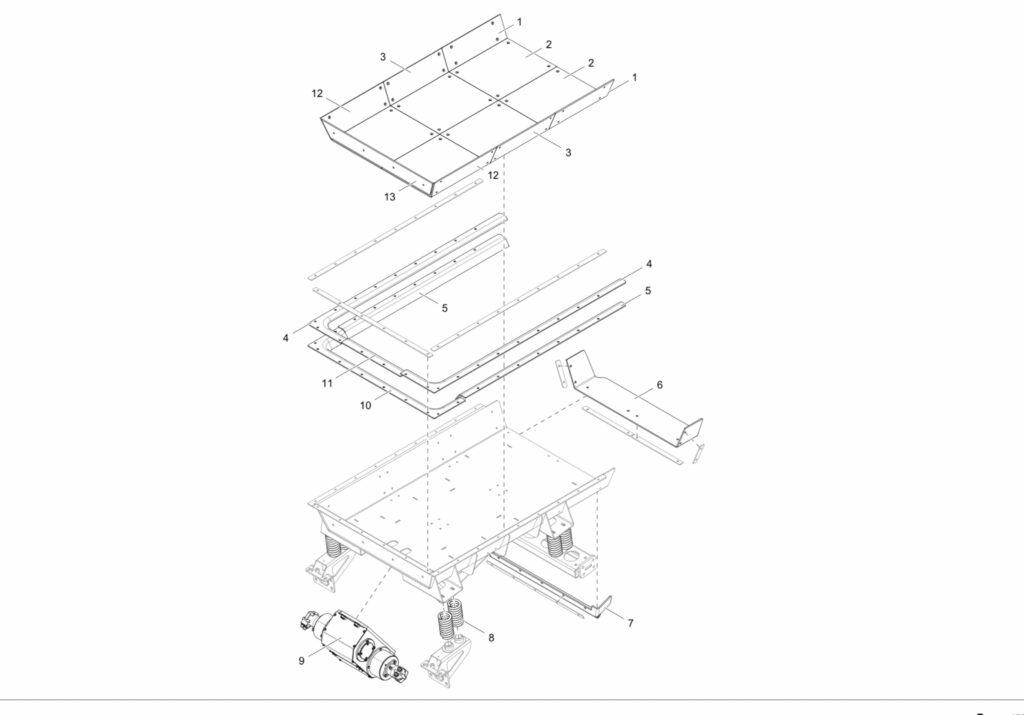

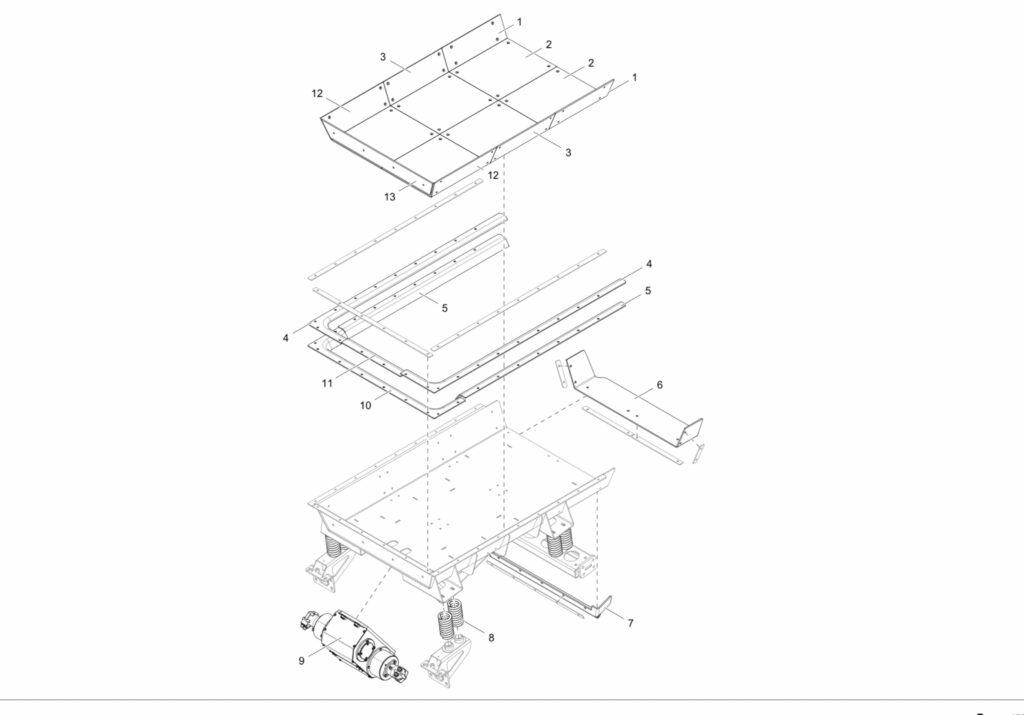

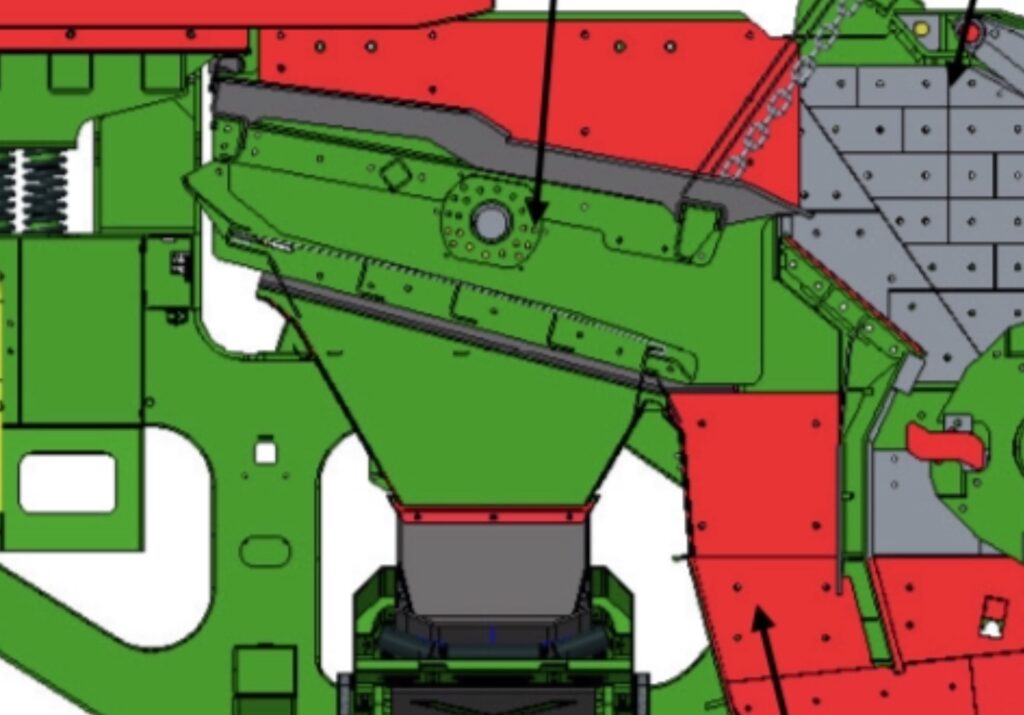

A robust double-deck pre-sieve with 6° inclination for efficient sieving with low energy consumption.

A powerful vibrating feeder for material feeding, driven by hydraulics with a double swing shaft, controlled by a high-pressure flow controller.

A vibrating chute for discharge under the crusher spout, driven by a dual-shaft vibrating motor that ensures optimum G-force even under wet working conditions.

A substantially sized double-deck screening box for post-screening the crushed fraction, with a 26° inclination to efficiently handle high capacities.

An optional single-deck screening box is available, equipped with 1.5 laterally tensioned screening nets.

Sieve deck dimensions: 4280 mm long by 1830 mm wide.

The dump chutes under the pre-screen have vertical walls to direct the material to the discharge conveyor and vibrating chute, with minimal risk of adhesion in wet weather conditions.

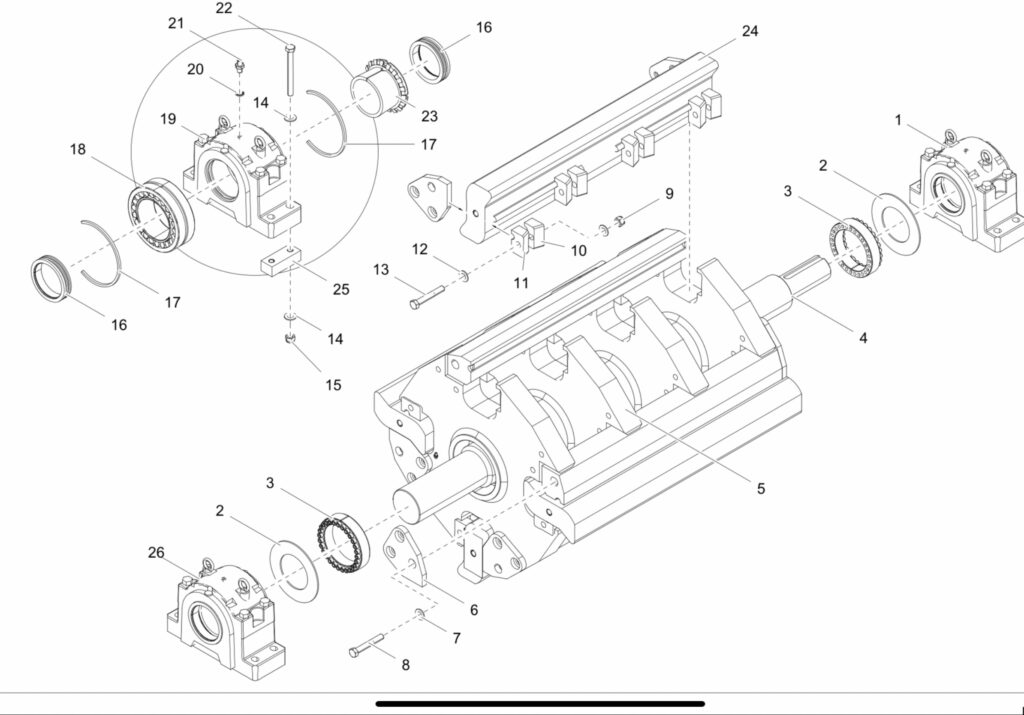

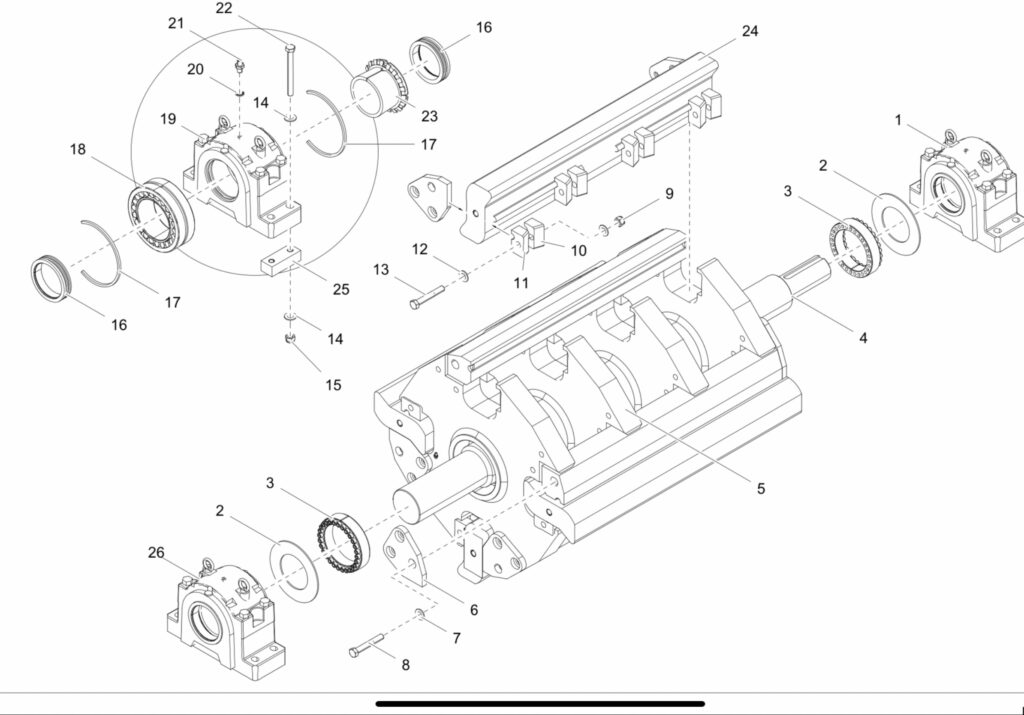

The crusher body of a mobile debris crusher is equipped with double, free-hanging counter frames that operate by gravity and spring tension.

The mechanical adjustment of spring tension is controlled via threaded rods on both sides of the crusher body. The adjustment of the CSS is done using a hydraulic adjusting cylinder with thickness plates.

Crusher CSS setting is of high reliability and low cost in maintenance.

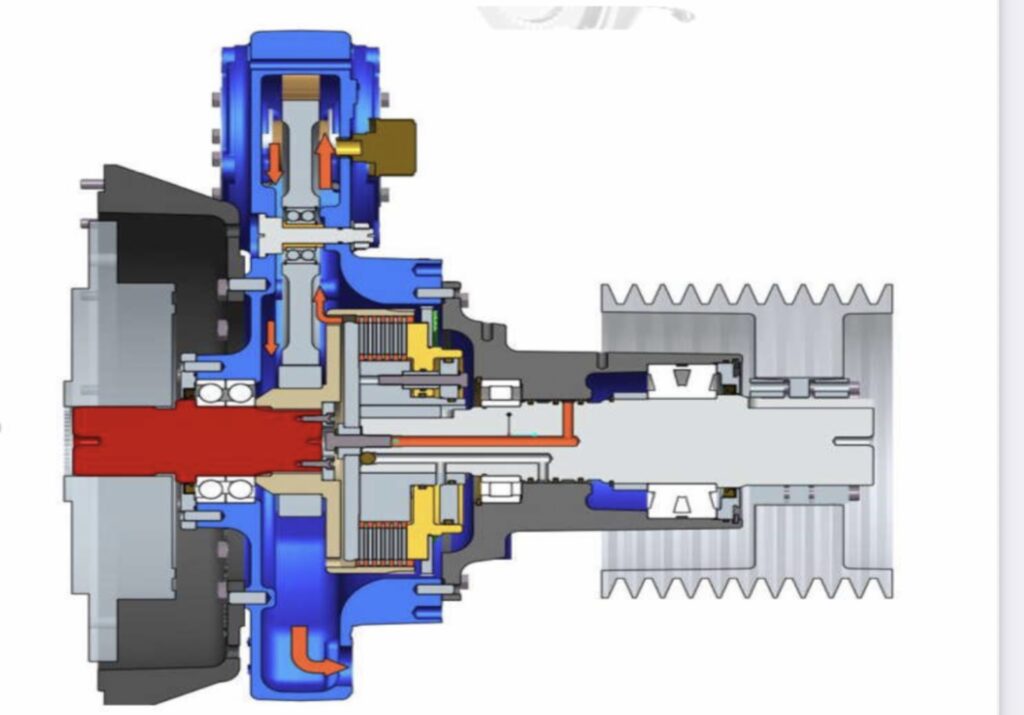

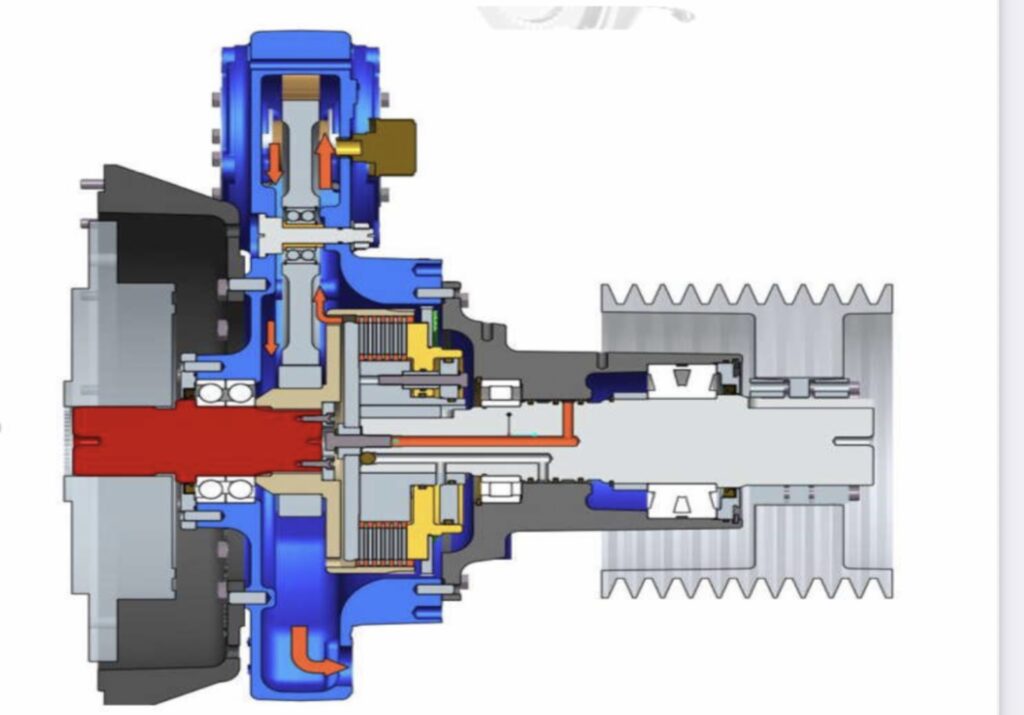

The rotor of a mobile debris crusher is directly driven by a PT Tech oil-cooled clutch, resulting in the most efficient energy consumption per tonnage produced.

This generously sized, intelligent clutch features hydraulic cooling and will immediately disengage when overloaded to protect components from damage in the event of a jam.

Direct drive minimizes energy loss between the drive motor and the rotor, resulting in significantly less fuel consumption per ton produced compared to alternative drive systems.

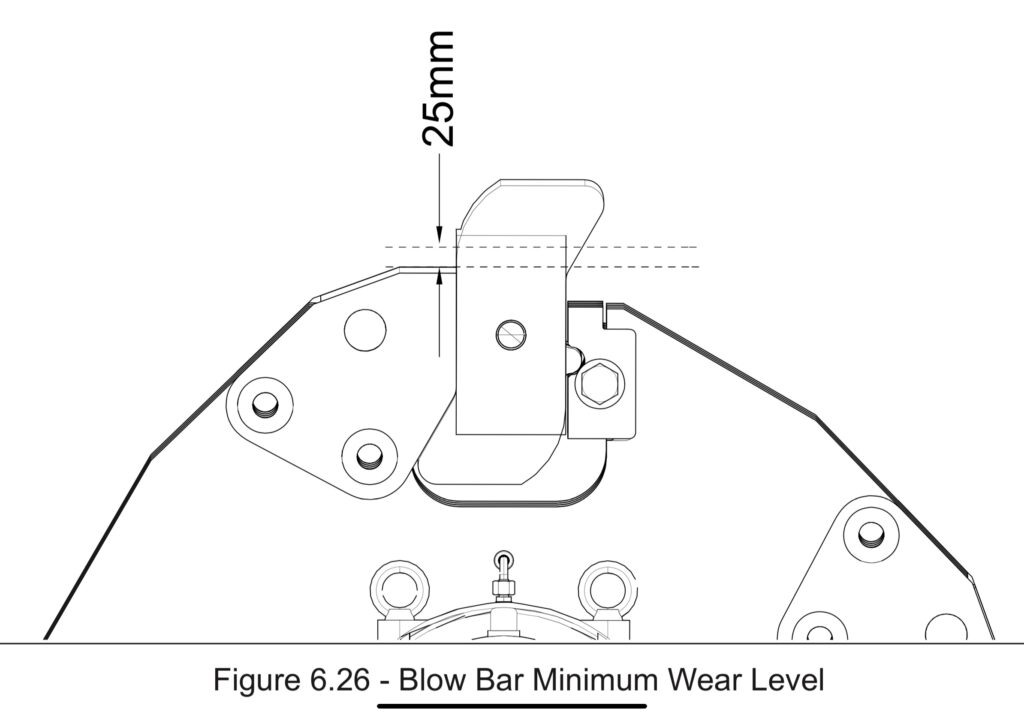

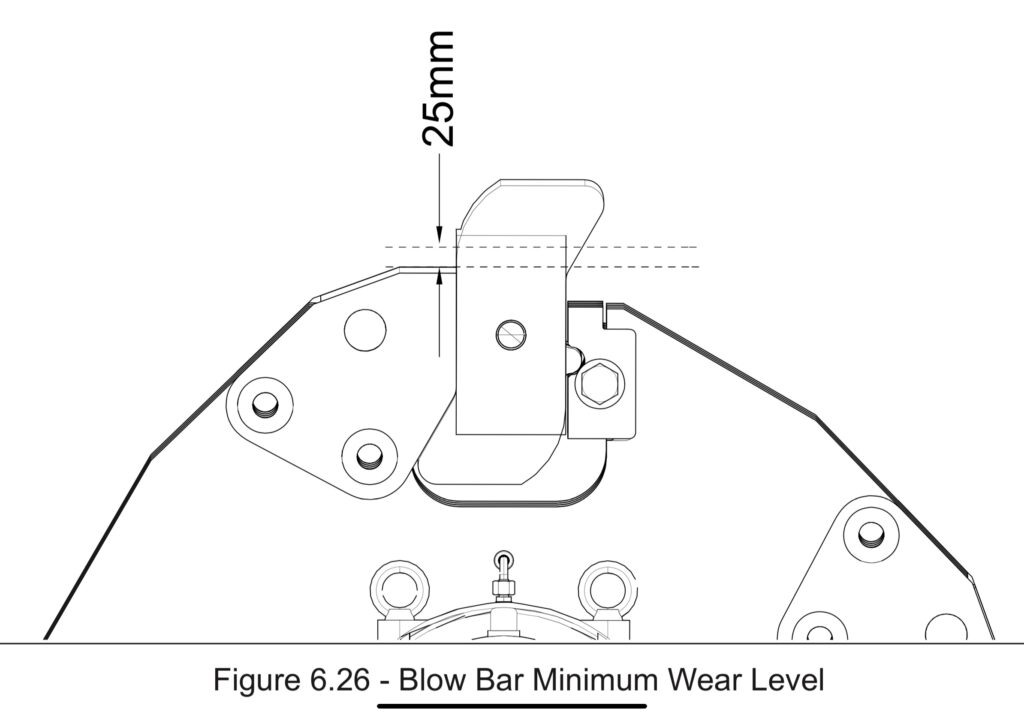

An open rotor with four striker strips, each attached to four supports, provides excellent stability and resistance to impact.

open rotor with four battens

The wear parts can be removed vertically for quick and effortless replacement.

Very high operating reliability thanks to simple controls.

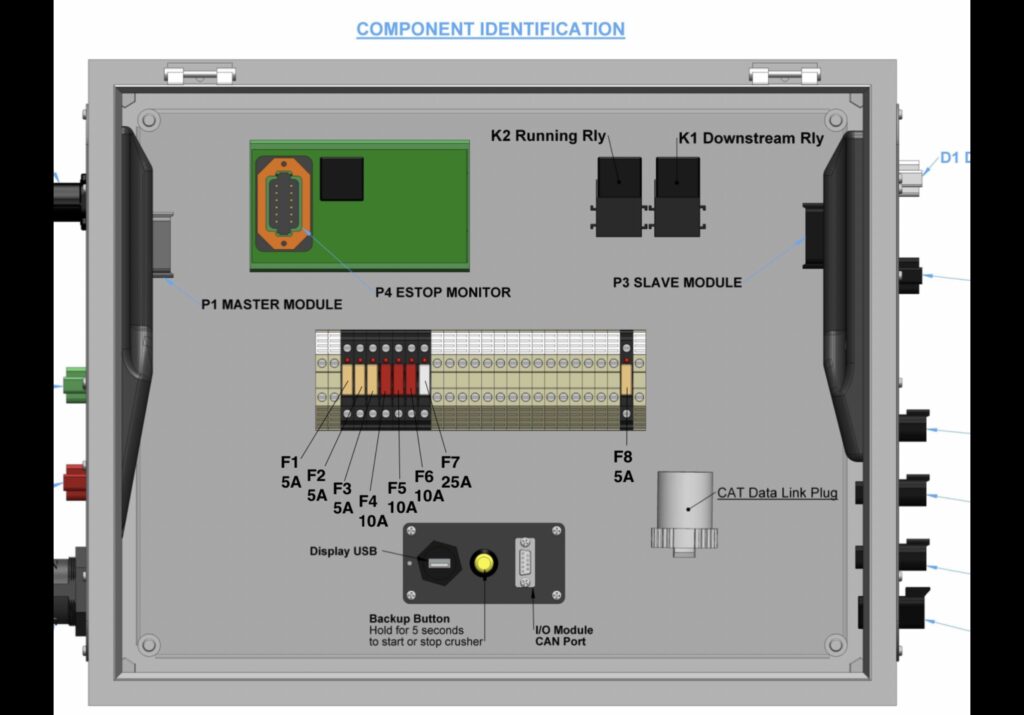

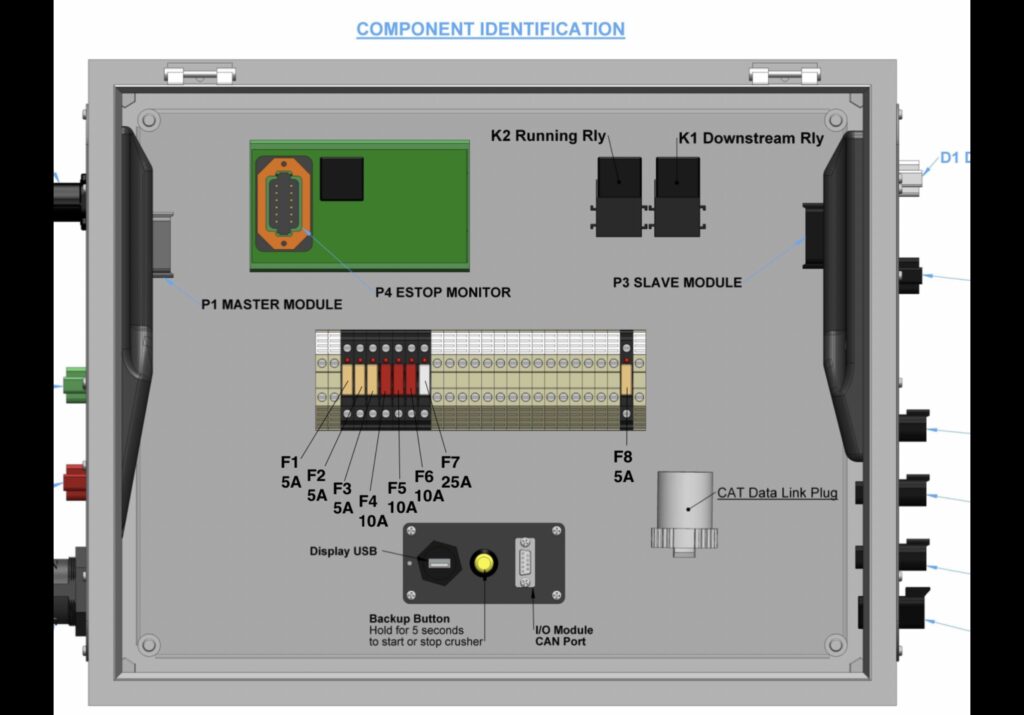

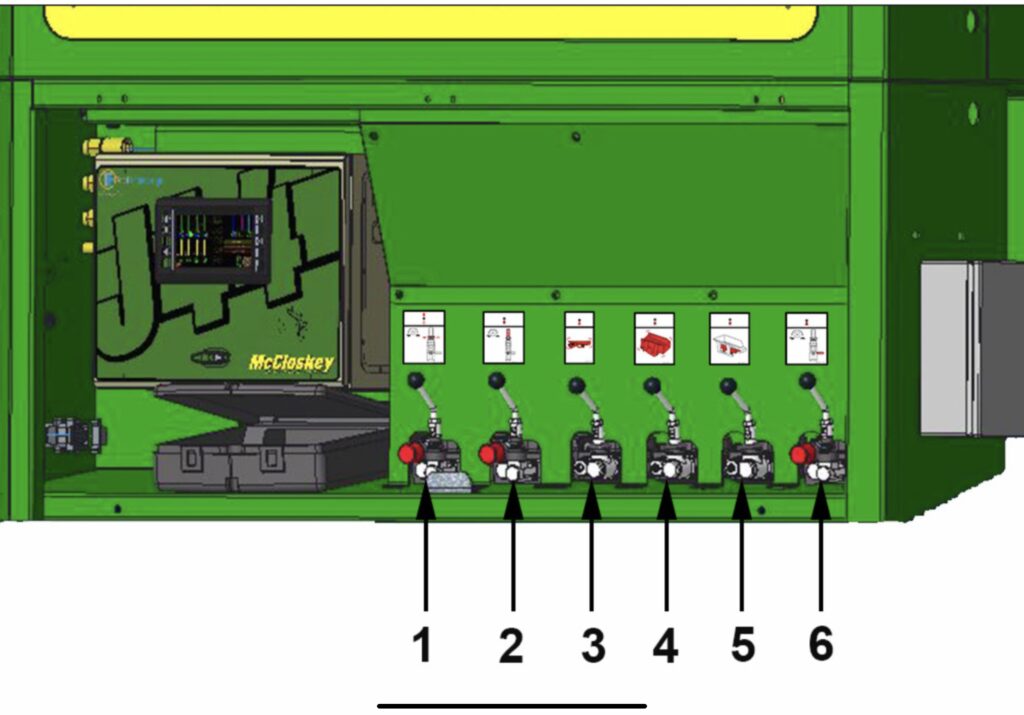

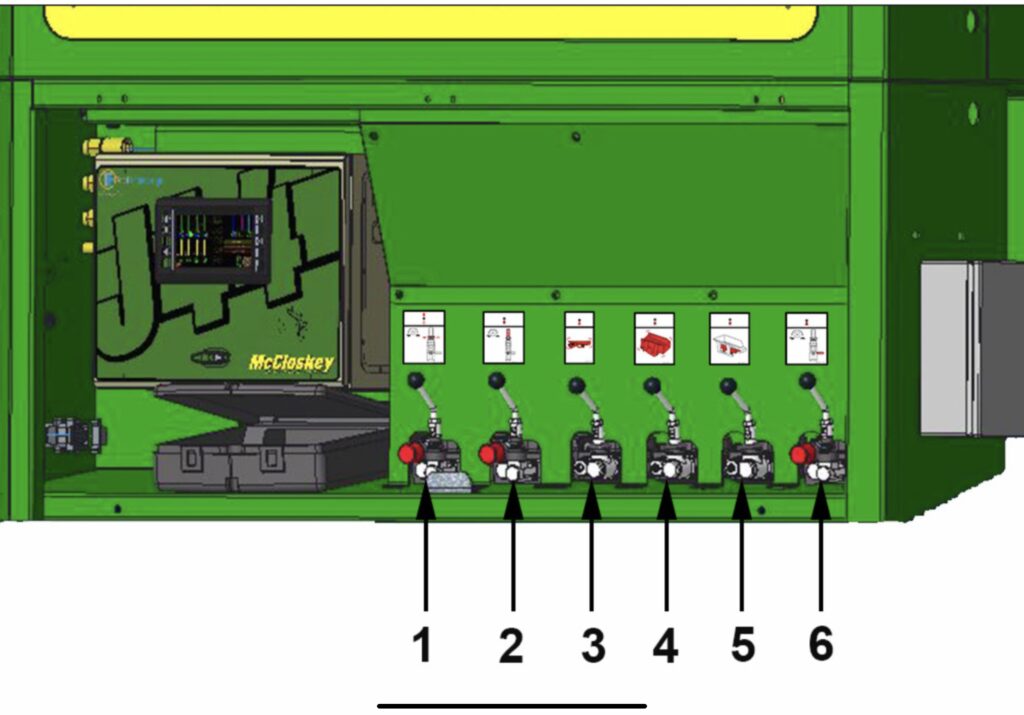

outside control box

inside control box

The hydraulic drive of all conveyors and tedding elements, with independent and infinitely variable speed control, guarantees maximum drive torque under all conditions.

Please contact us for free more information info@naessens-hydraulics.be