The science behind crushing with a VSI with the goal of producing high-quality granules.

The principle behind a Vertical Shaft Impactor (VSI) breaker is rooted in the fundamental principle of conservation of energy. This principle states that the total mechanical energy of a system remains unchanged when subjected solely to forces that depend on position and composition.

In order to introduce the most energy-efficient crusher on the market, we believe that five key physical components must be considered when investigating the complexity of the three-dimensional forces and projection of the material:

1. free fall of a body with variable mass and geometric configuration

2. conversion of energy and impulse

3. internal and external ballistic properties, including initial projectile velocity and impact force over time

4. converting the physical properties of solids into a fluid model and replacing Newton's classical physics with Bernoulli's dynamical-kinematics of fluids.

5. the friction

VSI breaking process

When the five major physical components of the VSI come together in a three-dimensional real-time mathematical model represented by various functional relationships, a mathematical model can be calculated. This allows us to observe the collision process and forces to identify solutions for improved process energy efficiency. These contributions lead to lower production costs and a better final product.

By using advanced generation innovative computer applications, one is able to convert the mathematical model to CAD programs such as Solidworks and Matlab.

Advantages of VSI crusher:

- Large throughput

- Low energy cost

- Product with cube shape

- Reduces flat or chipped material to desired product.

- Meets strict product qualification standards

- High production yield

- Produces granules and fine fraction

- Easy maintenance

- Low wear cost per ton

Operating principle:

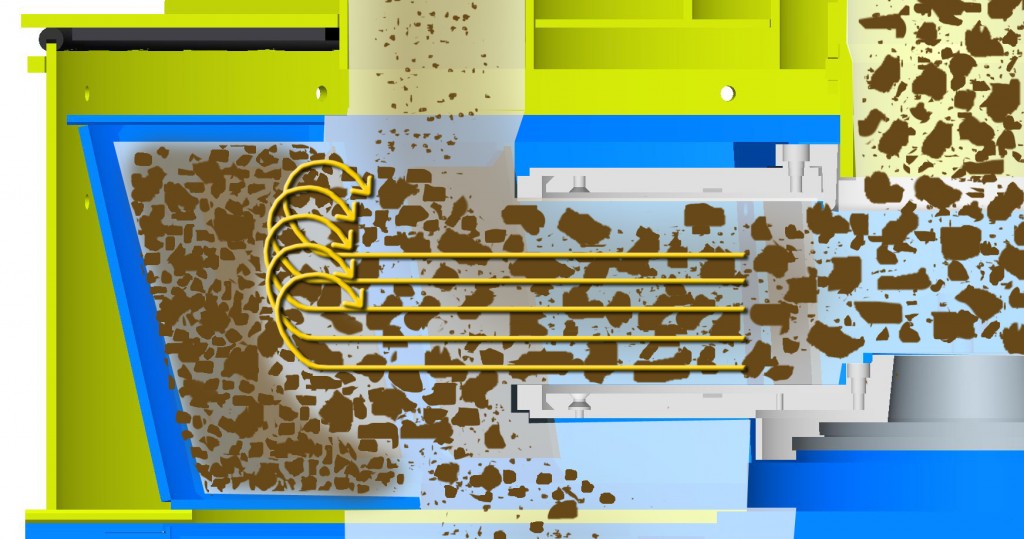

The feed material falls from the feed hopper onto the rotor table or into the closed rotor. It is then projected outward by centrifugal force against stationary hammers made of composite steel.

When the material hits the stator plates, it explodes due to impact along the natural fracture lines of the rock, resulting in a uniform, cubic product.

The rolling angle of incidence of the material against the stator of steel or stone creates granules with both round and cubic shapes.

This breaking method is a simple and very economical procedure.

In a later blog post, we will elaborate on the calculation of the VSI crusher wear cost in different product applications, another important pillar of the efficiency of the VSI crushing process.

Stay informed by subscribing to our news feed.

For more information related to rental or purchase of a machine please feel free to contact usinfo@naessens-hydraulics.be

or for a product analysis of your material to be crushed contact filip@naessens-hydraulics.be