The McCloskey J50 mobile jaw crusher has confirmed its reputation as one of the most productive mobile jaw crushers in the 50-ton class available worldwide today.

With prominent features

Including a true 1270 mm wide inlet jaw crusher fed by a 1220 mm wide vibrating feeder, fully hydraulic toggle, independent double-deck pre-screening and a 4200 mm storage height for the material produced, the J50 ranks in the A-class category.

mobile jaw crusher, mobile jaw crusher

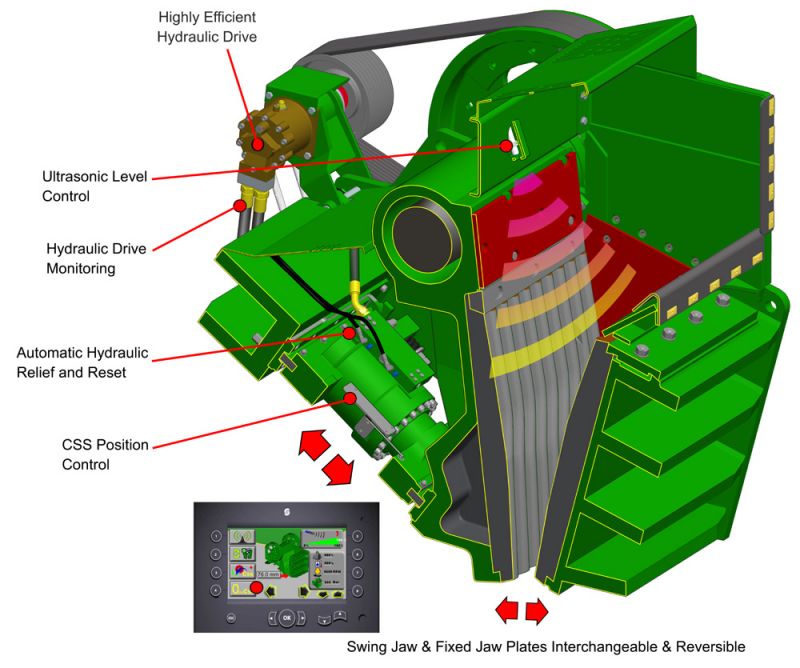

The heart of the J50 is the leading Telsmith jaw crusher with the unique features as follows.

Features of the mobile jaw crusher

Hydrostatic drive:

Highly efficient hydraulic drive in both directions of rotation of the crushing unit. Thanks to the hydrostatic drive, one obtains a smoother load curve of the diesel engine despite the high load peaks in the crushing chamber, resulting in lower fuel consumption and longer life of the drive components.

Ultrasonic level measurement in the crushing chamber.

The level of the feed material is continuously measured by means of an ultrasonic sensor which proportionally controls the feed hopper to automatically maintain the set operating level in the crushing chamber. This ensures maximum efficiency of the machine and ensures that the crushing chamber does not run empty regardless of the hardness of the material to be crushed.

Automatic toggle.

By means of a hydraulic cylinder arranged vertically on the moving jaw, the discharge opening is adjusted. This also ensures that, in the event of an overload or an uncrushable piece in the feed material, the moving jaw retracts and relieves the crushing chamber.

CSS position control:

After an overload, the hydraulic cylinder automatically resets to its set value. To achieve a uniform product, this setting is continuously monitored during operation and, if necessary, adjusted on the central control panel. All functions and set values are clearly arranged via a screen on the central control panel of the machine.

The wear parts:

The moving and fixed jaw, are interchangeable and separately reversible.

Discharge conveyor:

With a standard length of 13,500 mm, it provides a large stockpile capacity. This conveyor can be hydraulically raised and lowered and is quickly detachable for easy maintenance.

Power source:

CAT C9 ACERT 350 HP (261Kw) engine in a spacious engine compartment easily accessible all around and an innovative hydraulic system provides significant improvements for the benefit of fuel consumption.

Feed hopper:

Optionally manufactured entirely from Hardox hopper with hydraulically foldable doors for loading with a wheel loader.

Available options:

- Roll-in axle set for transport

- double deck independent pre-screener

- hopper extension

- overband magnet

- protection plate under crusher housing

- water pump and dust suppression system

mobile jaw crusher

For all inquiries: Naessens Hydraulics Oosterzele